Features

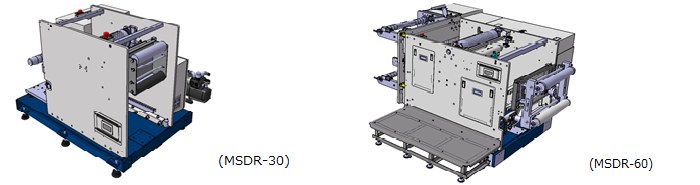

- Achieved to print on 25um film that can be used for thin electronic components as the internal base material of information terminals. (MSDR-30)

- High productivity obtained by cylinder type screen printing.

- High-level of printing accuracy provided by the functions of position detection and alignment via CCD camera.

- Various numerical settings are available with the touch panel.

- Reducing setup time drastically by automated screen frame initial positioning function. (MSDR-30)

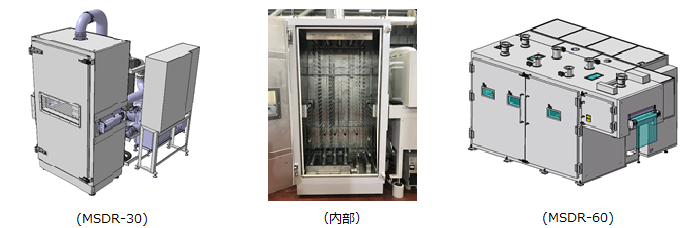

- The compact design dryers which were developed at the same time.

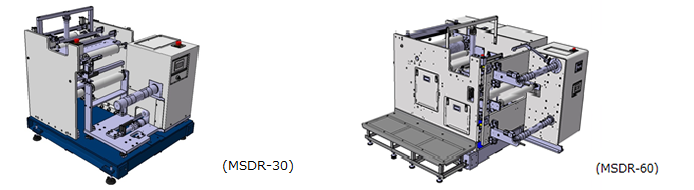

MSDR SERIES

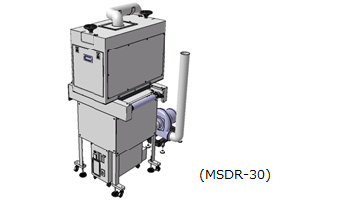

MSDR-30

MSDR-60

Suitable for advanced industrial screen printing, e.g., Multi-Layer Ceramic Capacitor (MLCC), Flexible Printed Circuit (FPC), biometric sensors like blood glucose sensor chip, membrane switch, and transfer printing.

Major Specifications

| Model | MSDR-30 | MSDR-60 |

|---|---|---|

| Max. web width (W) (mm) | 300 (11 13/16") | 600 (23 5/8") |

| Min. web width (W) (mm) | 150 (5 29/32") | 300 (11 13/16") |

| Web thickness (um) | 25 ~ 188 (0.001 - 0.007") | 38 ~ 188 (0.0015 - 0.007") |

| Max. print size (W x L) (mm) | 250 x 250 (9 27/32 x 9 27/32") | 550 x 500 (21 21/32 x 19 11/16") |

| Max. screen frame size (W x L) (mm) | 650 x 650 (25 19/32 x 25 19/32") | 880 x 880 (34 3/4 x 34 3/4") |

| Max. processing speed (sec./shot) | 3 | 3 |

* Printing size, Web thickness and Processing speed are subject to printing materials and printing conditions.

Major Features (Including Optional Equipment)

- CCD Camera alignment system (X,Y)

- Screen Frame Positioning by Numerical Control

- Web Guide Devices

- Squeegee and Flood Coater Pressure Control by Servo drive Motor

*For MSDR-30, Flood Coater Pressure Manual Adjustment - Printing Stroke and Clearance Adjustment Control by Servo drive Motor

- Print length adjustment fucntion

- Plate initial positioning function *Only for MSDR-30

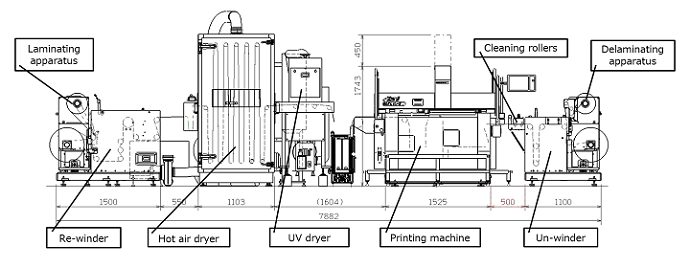

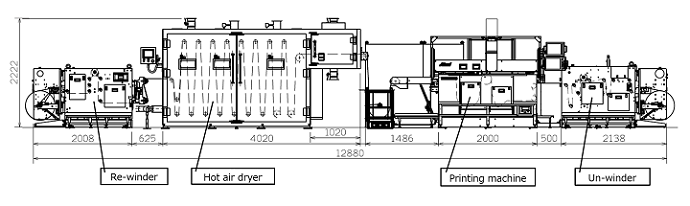

Reference layout drawings

MSDR-30 Single-color printing line

MSDR-60 Single-color printing line

Main components of MSDR Printing Line

Un-winder

- Unwinding speed regulation

The unwinding shaft detects the residual amount of material (web) and controls the feed amount and tension in conjunction with the winding shaft. - Web Guide Units

Adjust the web to the printing position by the movement of the unwinding shaft (laterally slides) and the guide roller (tilts) according to the web edge sensor. - Delaminator [option]

Peels the protective film while feeding the web. The web does not get damage since both work run at the same speed. - Static eliminator bar [option]

- Dust Cleaning device [option]

| Model | MSDR-30 | MSDR-60 |

|---|---|---|

| Chuck shaft dia. (inch) | 3 | 3 |

| Max. roll weight (kg) | 100 | 250 |

| Max. roll diameter (mm) | 400 | 600 |

| Film splicer | Standard | Standard |

| Tension setting (N) | 10 〜 60 | 15 〜 100 |

Re-winder

- Winding speed regulation

The shaft controls the winding amount and tension of material (web) in conjunction with the unwinding shaft. - Web Guide Unit

Correct the web meandering by the movement of the winding shaft (laterally slides) and the guide roller (tilts) according to the web edge sensor. - Laminator [option]

Attaches a film immediately after printing and drying process to protect the printed surface. The web does not get damage due to feeding in accordance with the winding tension.

| Model | MSDR-30 | MSDR-60 |

|---|---|---|

| Chuck shaft dia. (inch) | 3 | 3 |

| Max. roll weight (kg) | 100 | 250 |

| Max. roll diameter (mm) | 400 | 600 |

| Tension setting (N) | 10 〜 60 | 10 〜 70 |

Hot Air Dryer (Vertical, Turn type)

- Air turn bars enable to transport web without contacting the printed surface.

- Space-saving achieved by vertical conveyance.

- Input/output control via the operation panel at the printing section.

| Model | MSDR-30 | MSDR-60 |

|---|---|---|

| Thickness of material (um) | 25 〜 188 | 38 〜 188 |

| Carrying Length in furnace (m) | Approx. 20 | Approx. 30 |

| Atmosphere temp in furnace (deg C) | 60 〜 150 | 60 〜 120 |

UV curing device

- Equipped with UV lamp x1 (high-pressure metal halide, height adjustable)

- Input/output control via the operation panel at the printing section.

| Model | MSDR-30 |

|---|---|

| Thickness of material (um) | 25 〜 188 |

| UV lamp output (w/cm) | 120 |

| Output regulation (mm) | 400 |

* The specification given above is just one example. We will propose the most suitable ones depending on the purpose and requirements of the customer's work.