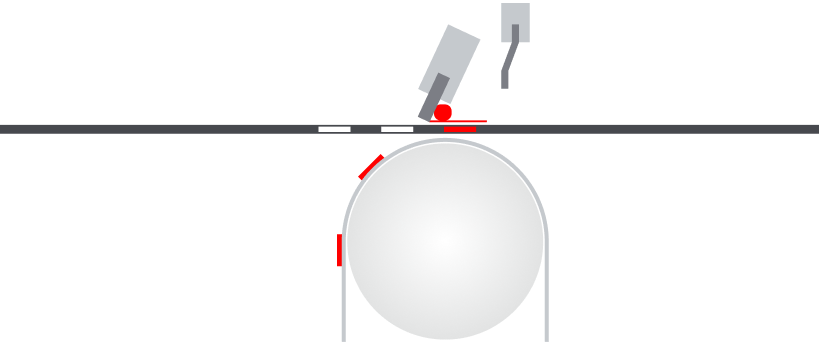

Screen-printing is a type of stencil printing in which ink is printed on an object by passing through holes in a silk gauze stretched over a screen. The feature of this system is that not only the shape of the pattern but also the thickness of the ink (printing film thickness) can be adjusted, allowing for a high degree of freedom in the act of printing. In the early days, silk cloth was used for the plate surface, so it was called silk screen printing or silk printing. Today, however, synthetic fibers such as polyester, which are more durable and precise, and stainless steel mesh are used for the plate surface, so silk has been omitted and it is often called screen printing.

In recent years, various technologies have been developed in response to customer requests and challenges, and the technology is now used in a wide range of fields and applications, including printing (coating) functional pastes as well as inks in the manufacturing process of precision industrial products.