Features

- High rigidity ensures high register accuracy even at high operating speeds (Max. printing speed 4,000 IPH).

- Squeegee impression can be controlled automatically thanks to the function of pulse motor.

- Large HMI and control panel centralised on the squeegee post for high operability.

What's "STOP CYLINDER"

Stop cylinder can achieve perfect accuracy in printing because the substrate is gripped only while the cylinder stops, resulting in no sheet movemnet.

-

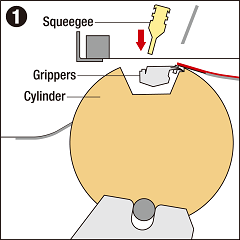

- 1. The grippers hold a substrate at the right position while the cylinder stops. Then the squeegee moves down onto the screen.

-

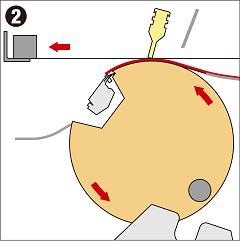

- 2. The squeegee moves down and printing starts at the top of the cylinder. The screen moves and the vacuum cylinder rotates.

-

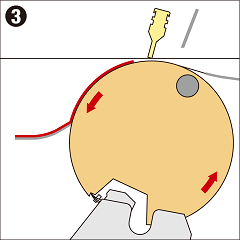

- 3. The substrate is delivered after being released by the grippers. The cylinder continues to rotate after the substrate is delivered.

-

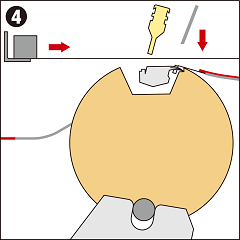

- 4. The screen frame starts moving back. The flo-coater starts moving down onto the screen when the squeegee lifts up. The cylinder stops for printing the next substrate.

Major Specifications

| Model | MS-80AII | MS-102AX |

|---|---|---|

| Feeder : Selection | Rear pick up feeder / Front pick up feeder | Rear pick up feeder / Front pick up feeder |

| Max. sheet size (W x L) (mm) | 800 x 550 (31 1/2 x 21 3/4″) | 1,050 x 750 (41 1/2 x 29 5/8″) |

| Min. sheet size (W x L) (mm) | 350 x 270 (13 7/8 x 10 5/8″) | Single feeding : 420 x 297

(16 5/8 x 11 3/4″) Stream feeding : 560 x 350 (22 1/8 x 13 7/8″) |

| Screen frame size (W x L) (mm) : Selection | 880 x 880 (34 3/4 x 34 3/4″) ( 930 x 880 (36 3/4 x 34 3/4″)) | 1,280 x 1,140 (50 1/2 x 45″) ( 1,300 x 1,170 (51 3/8 x 46 1/8″)) |

| Max. print size (W x L) (mm) | 720 x 520 (28 3/8 x 20 1/2″) ( 770 x 520 (30 3/8 x 20 1/2″)) | 1,020 x 700 (40 5/32 x 27 9/16″) ( 1,050 x 730 (41 1/2 x 28 7/8″)) |

| Sheet thickness (mm) *1 | 0.05 ~ 0.8 (0.001 – 0.031″) | 0.075 ~ 0.8 (0.002 – 0.031″) |

| Printing speed (IPH) | Rear pick up : 400 ~ 4,000 Front pick up : 400 ~ 3,000 | Rear pick up : 800 ~ 4,000 Front pick up : 800 ~ 3,000 |

| Machine dimensions (L x W x H) (mm) | 3,106 x 2,600 x 1,570 (122 1/4″ x 102 3/8″ x 61 3/4″) | 3,907 x 3,080 x 1,610 (153 13/16″ x 121 17/64″ x 63 25/64″) |

| Machine weight (kg) | 3,450 | 5,200 |

| Power consumption (kW) | 5.7 | 10.7 |

*1 Depends on the kind of printing substrates and printing conditions, figures may be changed

Standard Accessories

- Embossed stainless steel plate feeder board

- Press down feed rollers and brushes

- Pull side lay (80AII)

- Push / pull convertible side lays (R+L)(102Ax)

- Delivery board belt motor drive

- Delivery board lowering system

- Built-in front lay sensor

- Suction feed belts

- Dripless squeegee

- Screen frame pull-out device

- Screen frame air clamp device

- Ink drip pan (at frame pull out)

- Motorized squeegee pressure control

- Inverter speed control device (Digital indication)

- Preset couter

- Fixed rebound stopper (feeder side)

- Fixed rebound stopper (delivery side)

Optional Equipment

- Double sheet detector (Mechanial / Ultra-sonic)

- Piston sucker (Front pick-up feeder)

- Push side lay (80AII)

- Variety anti-static devices

- Sheet feed ball rack

- Movable rebound stopper

- Sheet cleaning roller unit (one side / both side)

- Smaller cyl.Vacuum holes (102AX)

- Screen part tensioners

- Cross over stand

- Air compressor (0.4kW)

- High pile (+300mm)

- Palettable feeder

- Smart cover

Achieve operator safety and improve the environment in the factory.