Features

- Suitable for high-end industrial printing applications

- Sheet alignment control can be realized by reading the mark on the printed sheet by a camera or sensor (optional).

You can see the machine's video.

(Automatic flat bed high speed screen printing press, MF-80VII)

Specifications

| Model | Standard | Camera sheet alignment system (option) |

|---|---|---|

| Maximum substrate size (mm) | 800 X 600 | 800 X 600 |

| Minimum substrate size (mm) | 350 X 270 | 420 X 270 |

| Substrate thickness (mm) | 0.1 ~ 1.0 *1 | 0.1 ~ 1.0 *1 |

| Maximum substrate weight (kg) | 1.0 | 1.0 |

| Maximum printable size (mm) | 800 X 585 | 800 X 585 |

| Maximum frame size (mm) | 1,100 X 1,000 | 1,100 X 1,000 |

| Minimum frame size (mm) | 760 X 660 | 760 X 660 |

| Maximum Printing Speed (IPH) | 1,000 *2 | 650 *2 |

| Dimensions (D x W x H) (mm) | 4,034 X 2,025 X 1,550 | 4,034 X 2,025 X 1,550 |

| Machine weight (kg) | 3,000 | 3,000 |

| Power consumption (kW) | 7.2 | 7.2 |

*1 It depends on the substrate’s characteristics and printing conditions.

*2 The denoted speeds are indicative of the mechanically possible performance The speeds are subject to variation according to the plate and substrate to be used and printing conditions.

Standard Equipment

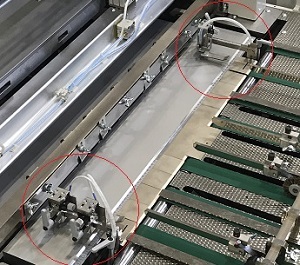

- Side edge detection sensor + side slide table type registration device

- One side operation system (printing plate position, squeegee and flood-coater pressure adjustments)

- Squeegee & flood-coater are quickly and easily attached

- Numerical indicators for several adjustment area

- Screen frame unit lift-up

- Screen frame move back to horizontal posotion

- Printing head lift-up

- Touch panel operation

- Delivery conveyor

- Front pick up feeder (independent operation)

- 300mm wide step (operation side)

Optional Equipment

- Camera sheet alignment system

- Dripless squeegee (swing type)

- Skew squeegee device (Max. printing area & printing pattern position are limited)

- Twice printing system

- Cleaning roller unit (Techni-clean roller)

- Static electricity eliminators

- Double-sheet detector (machanical,ultra sonic)

- Sucker nozzle timing change for thick and hard material

- CCD cameras for plate positioning

- 600mm wide step