What's "HOT FOIL STAMPING"

After curing the UV varnish printed on the substrate surface by screen printing, LQM EVOLUTION (LQM EVO) handle the process of thermocompressing the foil material to the varnish coating parts in one pass.

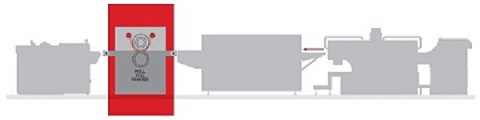

Configuration (LQM EVO Hot Foil Processing Line)

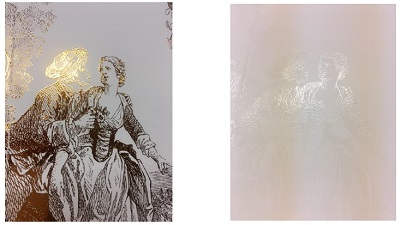

Hot foil effect

You can see the actual production line

(Fully automatic screen printing machine MS-102AX +

foil stamping machine LQM-105 EVO + inspection device SI-102IN)

Features of LQM EVOLUTION

- Versatility and low cost without using special foil mold.

- It makes possible to improve productivity while getting high-precision hot stamping effects only at the necessary points.

- High accuracy of registration because the foil can be put on multiple imposition.

- It can be installed as an optional processing function on an existing screen printing line(UV).

- Increasing in a size of foil web core diameter to 3 inches makes large diameter foil roll can be mounted which improve the productivity.

- The LQM EVO has alignment conveyor , thus the sheets are precisely transported to the foiling part.

- Adding new function of remote assistance enabled rapid online support.

Features of various foil stamping machines

| SAKURAI LQM EVOLUTION | Conventional Hot foil machine | Cold foil | Digital foil machine | |

|---|---|---|---|---|

| Metallic | ○ | ○ | △ | ○ |

| Reproducibility (definition) | ○ | △ | ○ | ○ |

| Registration accuracy in multiple imposition | ○ | △ | ○ | ○ |

| Embossing (excitement) | ○ | ○ | × | ○ |

| Mold | NO need | Need | NO need | NO need |

| Heat effect on materials | △ | × | ○ | △ |

| Running speed | 800 - 1,500 S/H | 5,000 - 9,000 S/H | 1,500 - 6,000 S/H | 500 - 1,500 S/H |

| Foil usage | △ | ○ | × | △ |

What LQM EVO can do

High-class production with foil stamping

Product: packaging material, etc.

Product differentiation and branding

Product: Package, book cover, etc.

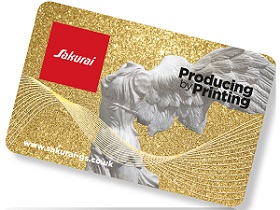

Hot stamping on various materials

Product: plastic material,Cards, clear files, etc.

Specifications

| Model | LQM-76 EVOLUTION | LQM-105 EVOLUTION |

|---|---|---|

| Substrates loading sizes | Minimum 350 x 270mm Maximum 760 x 520mm | Minimum 560 x 350mm Maximum 1,050 x 750mm |

| Substrates | Evaporated paper, plastic sheet, Laminated material, metal plate, various paper materials | Evaporated paper, plastic sheet, Laminated material, metal plate, various paper materials |

| Substrates thickness | 0.14 - 0.47mm | 0.14 - 0.47mm |

| Works mode | a) Partial foil mode (foil saving) b) Continuous mode c) Bypass mode | a) Partial foil mode (foil saving) b) Continuous mode c) Bypass mode |

| Foiling speed | a) Maximum speed 30m/min. (55 meter/min, Bypass mode) | a) Maximum speed 30m/min. (55 meter/min, Bypass mode) |